©2006-2016 Quince Automation Ltd (Quince Controls) Bedford MK42 7SY UK.

Easy access to Milton Keynes, Cambridge, Oxford & London.

Human Machine Interface ( HMI ) & SCADA Visualisation

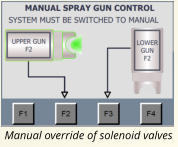

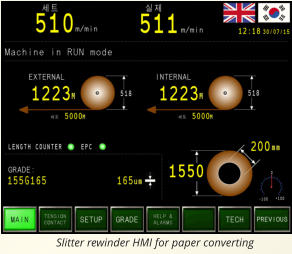

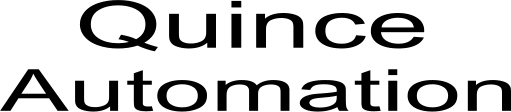

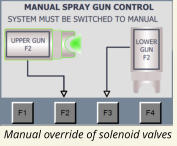

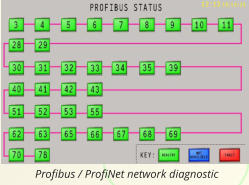

Adding a HMI to a PLC system opens up a host of possibilities for ease of operation, system diagnostics and asset management. Most modern control systems incorporate a HMI device; small machines may have a single interface whilst larger installations may have several HMI panels distributed at strategic locations for local control functions and possibly a master system located within the control room. Careful design of a HMI can simplify operator experience by limiting control options according to a process state or mode of operation. Help text and images can give detailed information on the function of control and your companies Safe Operating Procedures (SOP) can even be displayed as required. Quince Automation can design and program HMI interfaces to suit your new or existing application and we have previously used systems from :- Siemens Protool & WinCC Allen Bradley Panel Builder & PanelView, RSView Proface Beijer ESA Redlion PC applications in C & C# Adding a modern HMI devices to an older control system can unleash many additional features such as :- Remote connectivity Recipe management Data logging & historian facilities Fault Diagnostics and Event management Older PLC’s such as Allen Bradly SLC and Siemens S5 / S7 200 can benefit from the addition of a HMI to give access to modern communication options such as Ethernet, fault reporting and data logging to standard memory cards. The PLC can be replaced at a later date with little impact to the HMI program. HMI connectivity is not only limited to PLC’s, many Motor Drives and Motion Controllers can be directly interfaced to give quick access to controller status and parameters.

©2006-2016 Quince Automation Ltd (Quince Controls) Bedford UK

HMI - Human Machine Interface

Adding a HMI to a PLC system opens up a host of possibilities for ease of operation, system diagnostics and asset management. Most modern control systems incorporate a HMI device; small machines may have a single interface whilst larger installations may have several HMI panels distributed at strategic locations for local control functions and possibly a master system located within the control room. Careful design of a HMI can simplify operator experience by limiting control options according to a process state or mode of operation. Help text and images can give detailed information on the function of control and your companies Safe Operating Procedures (SOP) can even be displayed as required. Quince Automation can design and program HMI interfaces to suit your new or existing application and we have previously used systems from :- Siemens Protool & WinCC Allen Bradley Panel Builder & PanelView, RSView Proface Beijer ESA Redlion PC applications in C & C# Adding a modern HMI devices to an older control system can unleash many additional features such as :- Remote connectivity Recipe management Data logging & historian facilities Fault Diagnostics and Event management Older PLC’s such as Allen Bradly SLC and Siemens S5 / S7 200 can benefit from the addition of a HMI to give access to modern communication options such as Ethernet, fault reporting and data logging to standard memory cards. The PLC can be replaced at a later date with little impact to the HMI program. HMI connectivity is not only limited to PLC’s, many Motor Drives and Motion Controllers can be directly interfaced to give quick access to controller status and parameters.